| bootloader | ||

| conf | ||

| graphviz | ||

| hw | ||

| inc | ||

| lib | ||

| shared | ||

| src | ||

| stm32f103 | ||

| tools | ||

| .gitattributes | ||

| .gitignore | ||

| .travis.yml | ||

| base.mak | ||

| cleanup.sh | ||

| COPYING | ||

| Makefile | ||

| README.md | ||

| stm32_flash.ld | ||

Build Log: https://travis-ci.org/rene-dev/stmbl

DISCLAIMER

THE AUTHORS OF THIS SOFTWARE ACCEPT ABSOLUTELY NO LIABILITY FOR ANY HARM OR LOSS RESULTING FROM ITS USE. IT IS EXTREMELY UNWISE TO RELY ON SOFTWARE ALONE FOR SAFETY. Any machinery capable of harming persons must have provisions for completely removing power from all motors, etc, before persons enter any danger area. All machinery must be designed to comply with local and national safety codes, and the authors of this software can not, and do not, take any responsibility for such compliance.

This software is released under the GPLv3.

stmbl

There is a wiki. https://github.com/rene-dev/stmbl/wiki There will be documentation.

IRC: #stmbl on irc.hackint.eu https://webirc.hackint.org/#stmbl

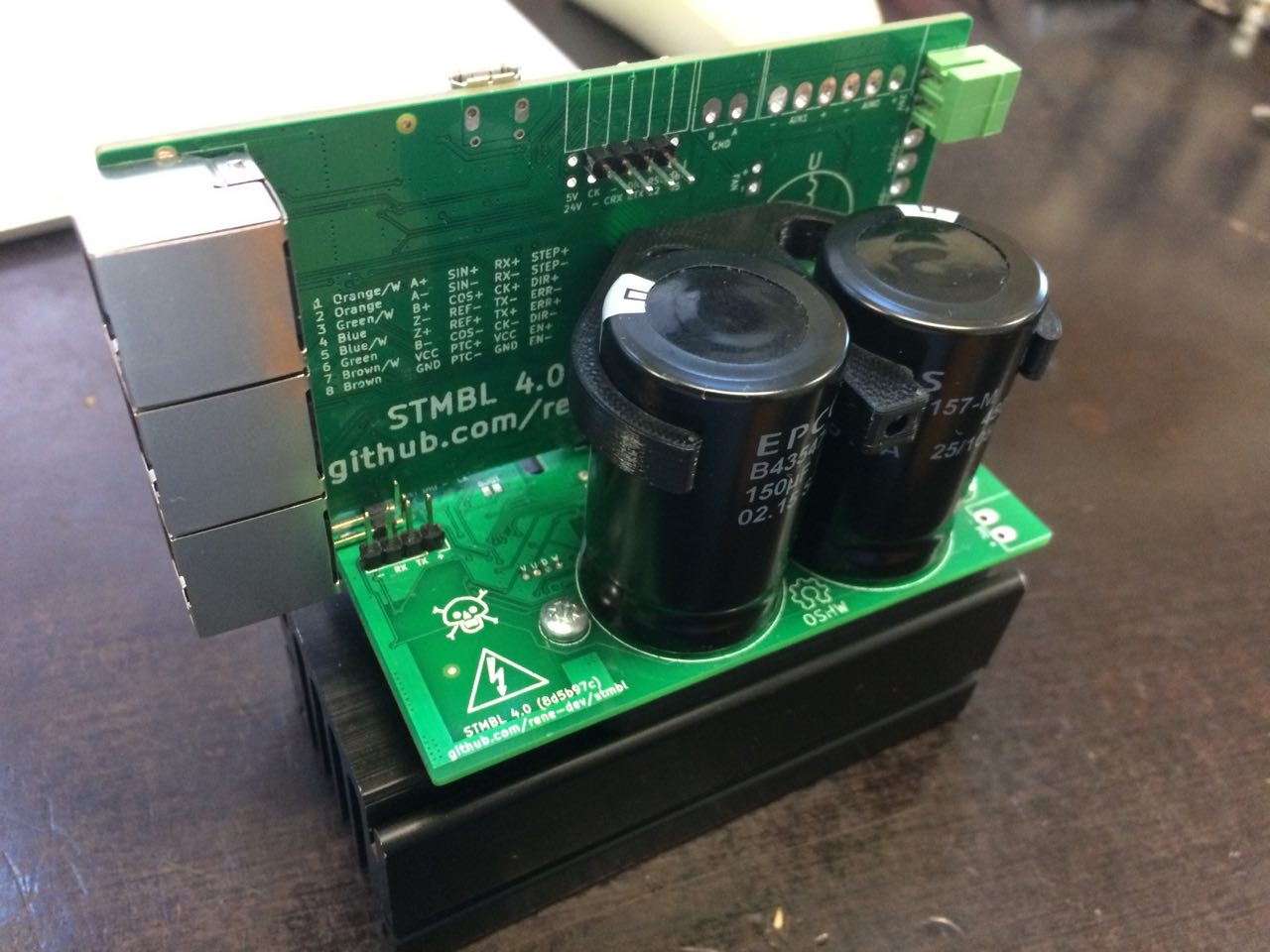

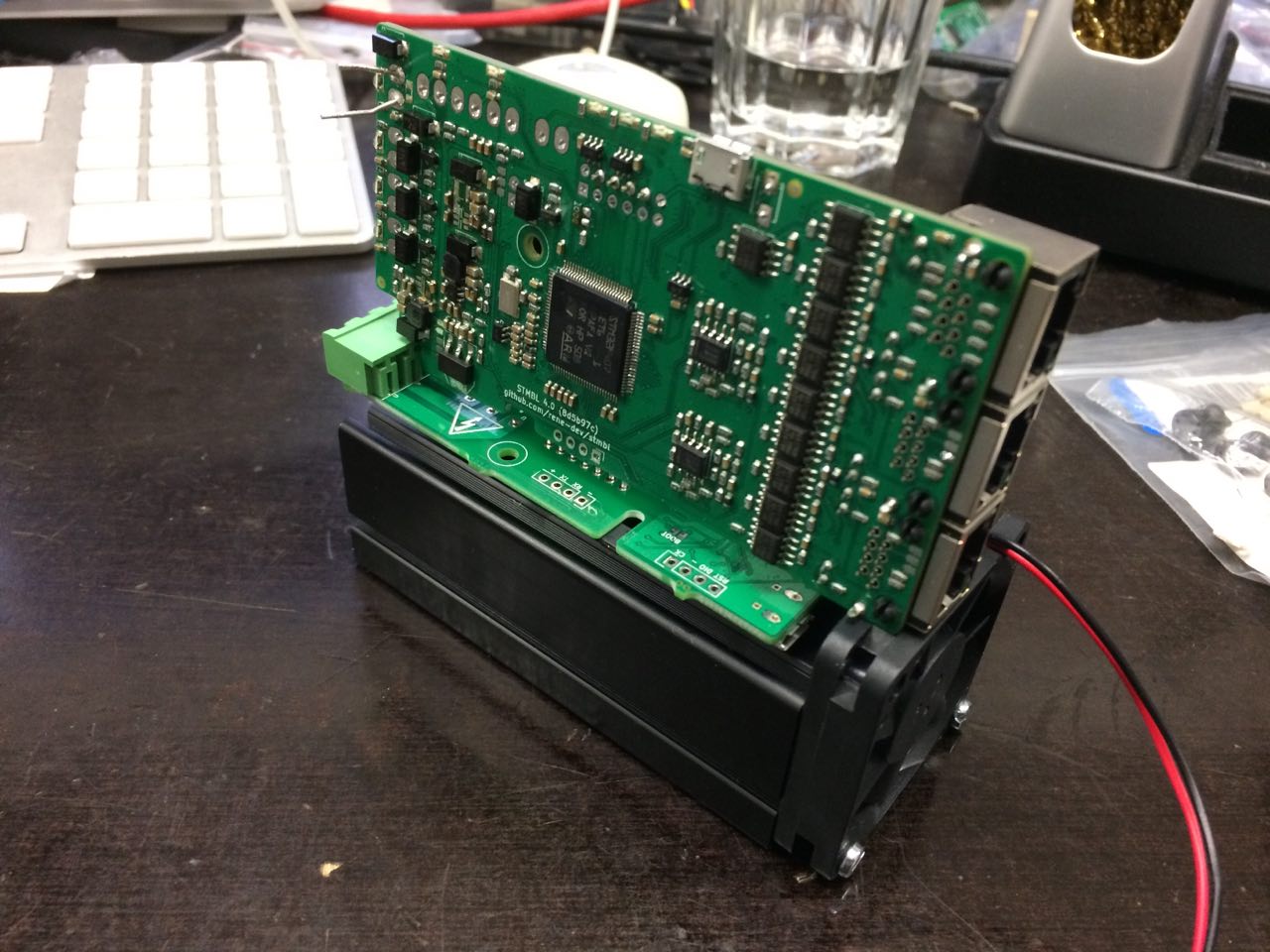

stmbl is an open source servo drive designed for Retrofitting CNC machines and Robots. It supports Industrial AC and DC servos with up to 320V and 1kW.

Documentation about the PCB and pinout of the feedback connector:

https://github.com/rene-dev/stmbl/wiki/Pinouts

https://github.com/rene-dev/stmbl/wiki/PCB

Hardware version 4.0

Driving a Bosch Turboscara

https://www.youtube.com/watch?v=d6NH1W7DUnQ

Driving a Manutec Robot

https://www.youtube.com/watch?v=gwgnAeGjZrA

https://www.youtube.com/watch?v=wXLcAZwjlzE

Drivetest

https://www.youtube.com/watch?v=-E1o_5cFyto

Supported Motors

- Synchronous AC Servos

- DC Servos

- 2 Phase HF spindle motors

- IRAMX Hardware testet up to 320V

Supported Feedback systems

- Resolvers

- Incremental encoders

- sin/cos encoder interpolation

- Mitsubishi absolute encoders

- Sanyo Denki absolute encoders

- Yaskawa absolute encoders

- Sick HIPERFACE®

Planned:

- EnDat

- BiSS

- SSI

- Sanyo Denki wire-saving incremental encoder

Supported Position/Velocity Commands Inputs:

- Smartserial

- Quadrature

- Step/direction

- RS485

TODO

- AC Async

Directories

- hw/eagle/ Eagle board files and schematics

- hw/spice/ Spice simulation for resolver interface

- src/ STM32F4 code, command, feedback and control loop

- stm32f103/ STM32F1 code, running on the HV side, generating PWM

- bootloader/ bootloader for the f4